Knife Edge Gate Valve

MOC: CI, DI & Gunmetal

The knife gate is a bi-directional wafer valve designed for media with high consistency. The double seat design assures a non-clogging shut off on either normal or reverse flow. The valve is used in a wide range of demanding applications in industries such as:

- Pulp & Paper

- Wastewater Treatment Plants

- Chemical plants

- Power Plants.

Sizes: DN 50 to DN 1000 (larger diameters on request)

Working pressure:

DN 50 to DN 125 10 bar

DN 150 to DN 250 8 bar

DN 300 to DN 400 6 bar

DN 450 5 bar

DN 500 to DN 600. 4 bar

DN 700 to DN 1000 2 bar

Standard flange connection:

DIN PN 10 and ANSI B16.5 (class 150)

Other flange connections are available on request such as:

DIN PN 6 DIN PN 16 DIN PN 25

BS “D” and “E” ANSI 125

Maximum Working Temperature : 45°C

Directives:

2006/42/CE (MACHINES)

2014/68/EU (PED) Fluid: Group 1(b), 2 (Cat. I, mod. A)

2014/34/EU (ATEX)

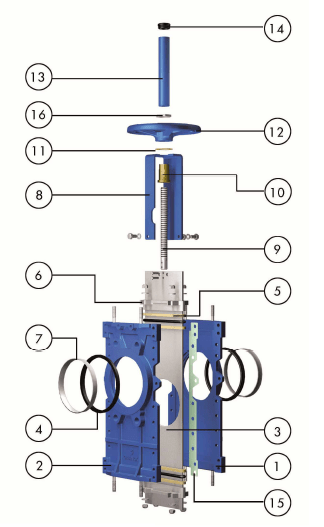

Knife Edge Gate Valve

| Part No. | Part | Cast Iron | Stainless Steel |

| 1 | Body | GJL250(GG25) | CF8M |

| 2 | Body | GJL250(GG25) | CF8M |

| 3 | Gate | AISI 304 | AISI 316 |

| 4 | Seat | Metal or EPDM | |

| 5 | Packing | PTFE Impreg. Synth. Fibre (ST)+O-ring | |

| 6 | Gland Follower | Aluminium (DN50-300) Ductile Iron (DN350-1000) | CF8M |

| 7 | Seat Retainer Ring | AISI 304 | - |

| 8 | Yoke | Carbon Steel - Epoxy Coated | |

| 9 | Stem | AISI 430 | |

| 10 | Stem nut | Brass | |

| 11 | Friction washer | Brass | |

| 12 | Handwheel | GJS400 (GGG40) | |

| 13 | Stem Protector | Epoxy-coated Carbon Steel | |

| 14 | Cap | Plastic | |

| 15 | Gasket | Aramid fibres | |

| 16 | Nut | Zinc plated Carbon Steel | |